大家好,我是 Gary。在过去的6个月,我采访了近100名国外的采购,其中近20名采购已经成为了我们团队的导师顾问团成员。

采购视角的一手信息,对外贸人来讲,可以说价值千金。一个销售项目(采购视角来看就是采购项目)会失败,本质上,是销售视角/行为和采购视角/行为的错位,错位越大,项目失败的风险性就越高,错位越低,匹配越高,成功率就越高。

采购案例分析

下面4个采购案例,是在采访中整理出来极具代表性的失败和成功的案例,大家对号入座,在评论区打出你的想法。

失败案例1:南欧化学原料树脂采购, 1500万欧元买家自述

Product range/product specs: I buy sometimes chemistry ‘ingredients'(technology aid and colouring additives, raw materials like resins, waxes, fillers, etc.) for plastics items producers (plastics parts, profiles, films, sheets, etc.) – only when prices are OK.

How we met: We met first on Alibaba, they were verified as ‘Gold Supplier’ there.

Price competitiveness: Prices were good so we placed a first order, before final (second) payment China sales girl started crying saying that she made mistake and price is higher. Now prices are by far less attractive for some ingredients, so we start looking for sourcing from Vietnam.

Quality: Samples were good, commercial delivery was bad, we made Claim to Alibaba which resulted in nothing!

Culture: Product Spec that we agreed at the beginning, was too short and we did not realized this fact. We made mistake to trust people with whom we never met in real, who’s factory we never visited, they turned out to be a middleman small company in Hong Kong, representing big group of SME Chinese producers.

• Now we work only with real producers who’s factory we visit, we look for TRUST!

失败原因

原因1:价格前后不一,可能是因为报价失误导致,可能是因为供应链的原因导致。

原因2:样品和交付产品质量差异。

原因3:产品规格沟通错位。客户识别出销售方为中间商,可能是一个 Soho 个人,彻底失去信任。再次说明供应链关系的重要性。

失败案例2:比利时9700万欧元飞利浦电子配件采购商

Product range and specs: We work as ‘outsourced sourcing provider’ for big companies like Philips. We source electrical, metal, mechanical and plastic parts from 20 countries and re-sell these items to them. All these parts are Class C (small volume and value) for them. (Sourcing of Class A and Class B components they do ‘in house’.

How we met: I do not know, it was far before I joined company.

Price Competitiveness: In spite of the fact that we have office in China, we gradually moving sourcing from there to India and Central Europe. Price competitiveness is not enough nowadays, we are asked by our Clients to validate Social.Responsibility,Environmental Sustainability, Supply Chain security (and we do not want to hold inventory in Europe), so for our Clients we rather choose ‘Security option’ but not ‘Low Price option’.

Quality: Quality and its stability remained (in past) an issue, so we are moving out, but approval of new suppliers with our Clients takes time!

Culture: English language in India is better, we often see that Chinese factory has European ENEC Certificate in the entrance hall, but what we see on their production floor puts the question – how they got it? We can not trust them!

失败原因

原因1:对于 Philips 这种大型客户需要的 CSR 等认证,中国中小型外贸公司无法提供。

原因2:ENEC(欧洲的电器产品安全证书)的可信度,在采购视角看来存疑。

失败案例3:北欧3500万欧元灯具、声学设备、电脑屏幕和电电子元器件采购商

Product range, product specs:

• Our projects sometimes require a wide product range, and no one of China’s producers can offer it!

• They do ‘Copy-Paste’ products from European/US samples which get from biggest in the world fair L&B in Frankfurt.

• Our Spec for Media screen ordering was sophisticated and covering 86 parameters.

• Bespoke products – no way to source from China!

• I buy housings and metal parts from China already for 10 years. In North Europe 10-15% of lighting market are products from China, but all assembled locally.

How we met:

• I met with Chinese Supplier on trade show in China, to where I came on purpose to find good Suppliers.

• The selection of Suppliers was done in China based on meetings during fairs and factory visits.

Price competitiveness:

• Finished product assembly costs in China now are at par with Central Europe, and quality of assembly is bad!• Plastics components – at par price with Europe.• Metal ones – good prices vs Europe.

• Electronic parts like drivers, LED modules COB, SMD) – at par with big brands like Philips, Tridonic (made in Europe: Poland, Ukraine, Serbia), but components from big brands like Philips are more miniature and more reliable.

• Import duties in EU 2-3%, which is not critical.

Quality: My visit to their factory shown – big plant with mass-assembly lines, but the quality is ‘not stable’. Poor quality of assembly and soldering, they easily change suppliers of electrolytic capacitors.

• The guarantee 12 months is just on paper, faulty units can be replaced in 6 months (which is too late!)

• Language sometimes an issue.

• The spare parts kit that we got with delivery – gone/used during the commissioning!

• One time we agreed to buy LED drivers: samples were good but commercial delivery was not (no approvals of changed spec was requested).

• Distant support (from China) is not working, only when they hired a local guy, it became better.

• QC and QA procedures are not working, they do not follow it.

• There are often damages during transportation (packaging is not for long distances).

Culture:

• If you ask for price reduction – Chinese people agree and can go down significantly, but they NEVER share with you that they are changing the Spec!

• Chinese sales people must know that Europe is hugely diverse in terms of culture, in buying behaviours, wealth level, time dynamic level,etc. Some nations might be perceived as stingy, some other – not, someone like bargain, other hate and walk out.

失败原因

原因1:对于稍微复杂一些的电子产品,参数众多,或定制化程度较高,北欧的客户无法在中国找到成品供应商,只能进口配件在当地进行组装。这也是为什么配件比成品更快见到订单。

原因2:同样,样品和交付产品规格、质量有差异。

原因3:中国供应商可以接受大幅度降价,但没有告知规格差异。

成功案例:南欧2300万欧元工业设备买家

Product range and specs: At first years we were visiting them BEFORE shipment to us, now we trust them. At first years they put labels/tags on the equipment in Chinese, we ask them to remove.

They do support with search of other (for them) auxiliary equipment in China, as Consultants Communication is done with Director-Owner, so decision-making timing is very fast in comparison with European Suppliers where managers-employees are much slower and less committed.

How we met: I met with this Chinese Supplier in China on trade show, to where I came on purpose to find good Supplier.

Price competitivenes: Prices are 7-8 times cheaper vs European ones! Lead times are much faster (45 days vs 9 months) .

Quality: Chinese equipment reliability is lower but ROI is much better vs. European equipment. Quality of plastic goods made using this Chinese equipment vs European rival equipment – is at par.

Culture:

• I like this Supplier as they are professional, their replies are usually very fast and informative (48 h).

• They have a big experience with supporting clients from countries like us (Slovenia).

• They are extremely committed which is not a case with big European brands who are lazy.

• Language sometimes an issue. But later they learned and started providing with Manuals in English.

• China’s equipment producers entry strategy into European market could be only via local acquisition and/or local. supply of spare parts

• Europe is hugely divers in terms of culture, buying behaviours, wealth level, time dynamic level, etc. Without local partner, consultant – there is no chance to win. European rivals do very good Marketing, Chinese people are weak on this.

成功原因

原因1:专业度,快速决策,快速反应。

原因2:对比欧洲的竞品,尽管质量稍差,但总体 ROI 较高。

原因3:有斯洛文尼亚市场类似项目经验。

大家看了这4个失败和成功采购项目案例,学到了什么?

可以执行的细节非常多,但我觉得核心是,像采购一样去思考一个销售项目。我们平时做的大量的思考、行为,都是站在工厂和贸易公司的角度,但是对采购在我们报价、沟通、验厂、样品、谈判的同时,他的心理状态和行为是怎么样的,这部分信息极度缺失。这导致了很多销售项目最终都是不了了之。没有下文。因为采购也不会告诉你为什么他们 walk away。

在上面的成功案例4中,客户的产品质量并不是最好的(跟欧洲的供应商相比),但是综合 ROI 是最高的。

那么,如果我们提前知道南欧的工业电子设备采购,是在拿欧洲的供应商和中国的供应商对比,并且对欧洲供应商的优劣势有一定的了解,我们在跟客户进行 pitch 的时候,是不是就可以做出更加匹配的价值主张,从而改变客户对我们的认知?

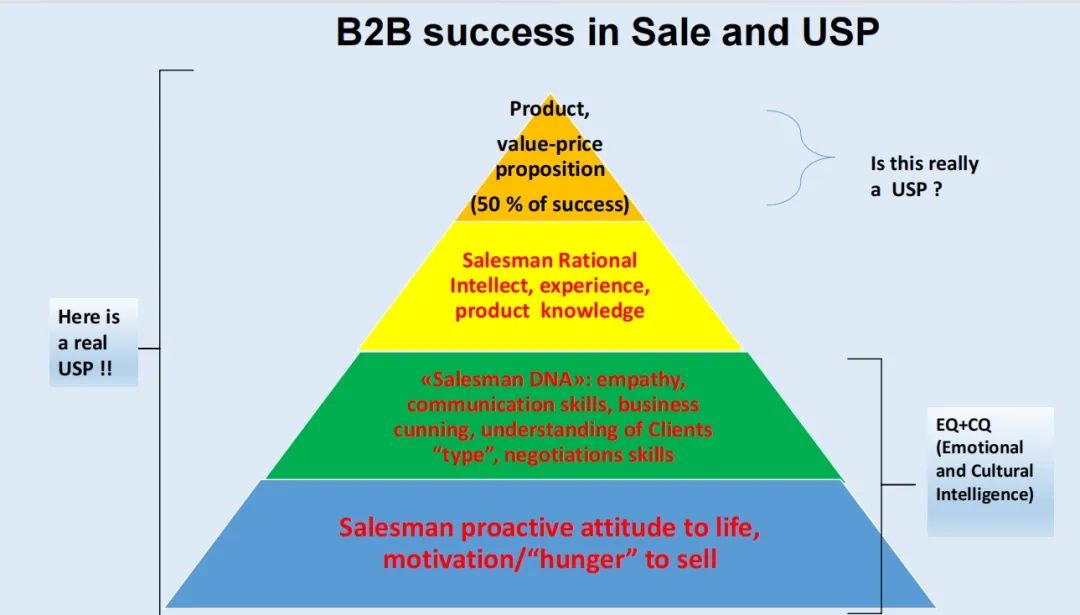

下面这个图言简意赅地说明了这个问题:

大多数人认为的销售都是停留在金字塔顶层的产品,价值,价格层面。但是,金字塔中部、底部的销售的理性、智慧、对产品和市场的认知、销售的 DNA、沟通能力、市场敏锐度、理解客户类型、谈判能力,统称销售的情商,这些东西,让采购导师团来给你做长期训练,是一种什么样的体验?

这些东西,只有采购能够告诉你。不论是你的公司的老板,资深的外贸老手,还是外贸培训老手,都没有让采购直接告诉你他们的一手信息来的重要和直接。甚至,让采购,客户,在课堂上进行 Role Play 谈判。这是快速拿到外贸销售订单最直接的路径。让你的潜在客户成为你的导师。

我们在11月20日即将上线的《千分之一训练营》可以说是市面上唯一能够带来如此暴力的价值输出的唯一选项。

训练营时长24周,24节训练课,超长陪跑。

一半由国外采购交付,一半由 Snov.io 营销专家交付。

从师资、内容上,我们做的都是降维打击。你甚至可能和你的导师进行业务沟通,成交订单,如果你们的产品 viable 的话,我已经跟采购导师团们沟通了这一点。

目前,我们的采购导师团,有欧洲的 LED、工业电子、消费电子、工业设备、家具、包装材料、服装、原材料等采购领域,采购的公司包括但不限于沃尔玛、Office Deport,Korber,Schreder,P&G 等大厂。我们的部分导师团成员为欧美市场的采购顾问,专门帮助欧美的大型公司实施采购项目。这些人平时作为咨询顾问的收费是500-1000 USD每小时。

做外贸,该跟你的客户学。面对这种抢一手采购信息的机会,但凡有点销售的饥饿感,报名不应该犹豫。把你的产品名称打在评论区,我会优先匹配评论最多的产品和最相关的产品的采购们交付我们的训练营项目。

加我微信提前了解《千分之一外贸营销业务训练营》: